| 0.1 | |

| Installation of system cabling |

| • | Cable must be installed within a controlled area |

| • | Cables are to be concealed |

| • | If cables are exposed to possible mechanical damage or tampering or visible in public areas, they should be protected by trunking or armor |

| • | Check release signal of an access point and if it exceeds the controlled area, use metal conduit or containment to amend it |

| • | The system must support all interconnecting wiring |

| • | Installation must conform to good working practice |

| • | Cable joints must be made appropriately i.e. wrapped, soldered, crimped, etc |

| • | Not to run low voltage and signal cables in close proximity to mains or other transient carrying cables |

| • | Low voltage cables from mains and standby power supplies to remote equipment are to be of sufficient size to permit sufficient operation of the equipment at the end of any proposed length of cable run |

| • | Cables are to follow contours |

| • | Cables shouldn’t run closer than 10.5cm to any fixing points such as the corner of a ceiling to a wall |

| • | Cables are to be sited away from door frame uprights |

| • | All wiring should travel in straight lines |

| • | Never run cables diagonally across walls |

| • | Apply containments to cable of they are likely to suffer damage |

| • | Don’t use jacketless cables |

| • | Do not pass cables close to steam or hot water pipes |

| • | Data and communication/signaling cables should be kept isolated from mains cabling and heavy current apparatus and wiring and only cross it at right angles |

| 0.2 | |

| Connection and testing of system components |

| • | Correct alignment of all the hardware to ensure that they function properly |

| • | Correct operation in accordance with the specifications of the hardware |

| • | Make sure that as the lock is energized or de-energized, it performs as specified for emergency purposes |

| • | Test whether the locks failing in the correct fashion fail locked or fail unlocked |

| • | Manual overrides functioning smoothly and overcoming any electrical malfunction |

| • | Ensure that all sensors give the correct response to the door position |

| • | Check the operation of door closers to ensure they pull the door closed with the correct force |

| • | Push-to-exit buttons should be verified for operation |

| • | Perform a test to prove that timers generate alarm activation when doors are open for longer than their preset period |

| • | Prove that the door lock remains energized for the timed period |

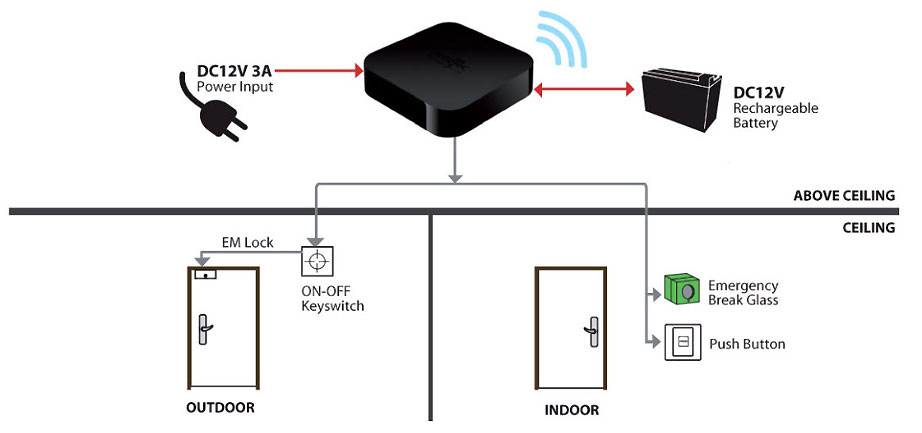

| • | 1 set of 12VDC switching power supply as a main power source to the entire door lock system | |

| • | 1 set of electronic door lock (12VDC type EM lock, drop bolt, or compatible models), max 2 sets if it is a double leaf door | |

| • | 1 set of magnetic sensor to serve as a door sensor for monitoring the door’s action and provide status feedback to TimeTec Access Hub. The door status includes Normal Open, Force Opened, Door Left Opened, which will be uploaded into TimeTec Access to alert the administrators during break-ins | |

| • | 1 unit of emergency break glass as circuit breaker to deactivate the electronic door lock in case of an emergency | |

| • | 1 unit of 12VDC rechargeable backup battery to keep the door lock system in operation during a power failure. Note: include more batteries to serve a longer standby time | |

| • | Optional Components : | |

| › | Push release button. Exclude this if you want to only allow authorised users to access the door | |

| › | Override key switch for overriding of the entire door lock system. Install the override key switch as a circuit breaker to deactivate the electronic door lock. Make sure that you secure the override key switch from any unauthorised individuals | |

| • | Visual inspections to make sure cables comply with the specifications |

| • | Ensure that no joints are made outside of junction boxes and that unapproved connection techniques are not used |

| • | Check for damage to the cores of the wiring and confirm that there is no missing insulation or that it is stripped back too far |

| • | No points in the wiring are to be stressed |

| • | Prove the consistency of the color codes |

| • | Ensure that the segregation of cabling from other cabling in the building is correct |

| • | Check for suppression being applied |

| • | Check cables within containments and that conduit is grounded |

| • | Verify the wiring routes are to the plans and follow the claimed routes |

| • | Ensure that the ambients of temperature that the cable is routed through cannot interfere with the performance of the wiring |

| • | The mains supply to the power supply should be correctly fused and be visually and electrically tested |

| • | Supplies to the access control system should be proved to be identified at their source |

| • | The power supply should have the efficiency of the earthing confirmed |

| • | Make sure that a UPS is in the location where maintenance can be easily carried out and that they are in a ventilated area, and installed in a location that’s secure from tampering |

| • | Local signaling should prove that any warning device or visual monitoring equipment receives the correct response in according with the transmission of a signal from the access control system |

| • | Any other security or building system or service integrated with the access control system should be verified as receiving an appropriate transmission |

| • | Door call units used with intercoms should be tested for audible and visual receipt at all appropriate points |

| • | A check should be made with the remote monitoring point or central station that the message that is to be generated is received |

| • | All data must be checked for correct entry |

| • | All alarms must be correctly displayed |

| • | All access levels with the times of access allowed must be verified |

| • | Operator levels are to be defined |

| • | Events must be shown exactly as they occur and as specified |

| • | All automatic systems feature as specified |

| 03. | |

| TimeTec Access Account Setup |

| 0.4 | |

| System Handover - Tests required at the commissioning stage |

| • | Name, address and telephone number of the controlled premises |

| • | Name, address and telephone number of the customer |

| • | Location and classification of each access point and the type of location of each controller and its associated hardware |

| • | The type and location of power supplies |

| • | Details of those access points which the customer has the facility to isolate |

| • | The type and location of any warning device |

| • | Details and settings of any preset or adjustable controls incorporated into the system |

| • | Any documentation relating to equipment |

| • | The number of keys, codes token etc to the system provided to the client |

| • | Correct termination of wiring |

| • | Voltage and resistance at all appropriate points of the system |

| • | Correct alignment and operation of access point hardware and of release and closure mechanisms at each access point |

| • | Correct operation of each reader |

| • | Release time for each order |

| • | Door held open signal, if specified |

| • | Verification of access levels |

| • | Function of system when mains disconnected |

| Following the completion of the handover, which should include the signing of contracts by both parties, the installer can confirm the need for maintenance and service and the schedule it is to follow. | |

|

Company

|

|

Policies

|

|

Customer Zone

|

|

Popular Links

|